- Maslow Cnc Assembly

- 12 Foot Maslow Cnc Frame

- Maslow Cnc Setup

- Maslow Cnc Frame

- Maslow Cnc Metal Frame

- Maslow Cnc Sled

Putting Your Maslow Together

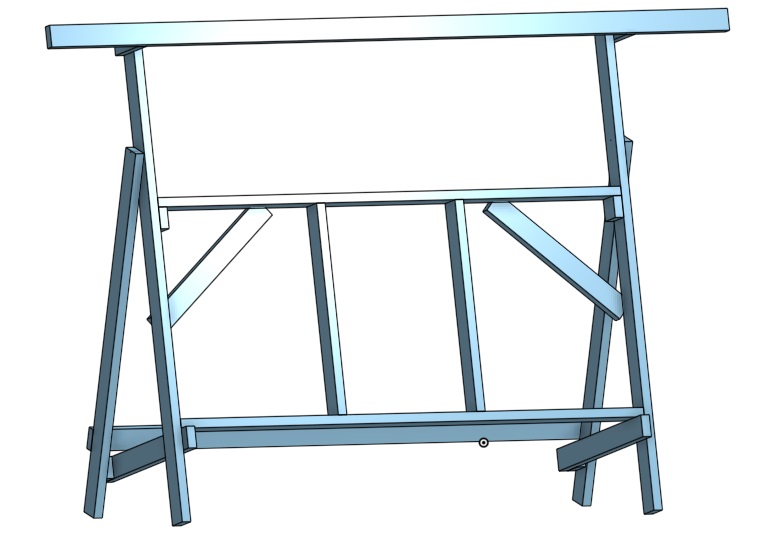

The default Maslow CNC frame This frame was designed as the result of a massive community collaboration. It is designed to replace the old default frame. It is designed to be built anywhere in the world so the dimensions of the lumber are not critical, and no hardware is needed other than screws and glue.

These instructions have been copied and updated from the original Maslowcnc.com site:

Because you provide your own router, build the frame yourself, and cut out the final round sled using a temporary sled that you cut by hand, the electro-mechanical parts of the Maslow can ship in a large USPS priority mail box. My Maslow is the 2nd generation that includes a ring for two chain carriages to roll along. New Frame Design. The design of the stock frame for Maslow is getting an overhaul. We’ve learned a LOT in the last year and we’re applying all of that knowledge to making the machine more rigid, easier to assemble, and cheaper! There is a vibrant conversation going in the forums about what the best way to do that is.

The goal of the Metal Maslow Project is to have a 4x8 CNC machine kit that is pre-programmed and takes little time to setup and calibrate. We have done our best to keep the kit affordable, but not at the expense of using cheaper less reliable hardware. The nice thing about buying the parts in bulk and reselling the kit is that the individual parts are much less expensive to make. Your feedback about how to make these directions better is more than welcome.

Building the machine is done in 4 steps. We chose to have our own directions since our kit is easier to setup and because of that the directions are a little different.

Maslow Electronics Setup

Step 1: Identifying Parts

There are 5 pieces to the electronics system. Shown in the picture below from left to right and top to bottom they are: 1. The Motor/Encoder/Gear Box Units 2. Motor Wires 3. CNC motor controller shield 4. Keystudio Mega 2560 micro controller(Arduino compatible) with USB Cable 5. 12V DC 6A / 110-250V AC Power Supply

Step 2: Attach Heatsinks

The Arduino shield is already attached onto the Keystudio Mega 2560 micro controllerwith our kits so all one has to do is attach the 3 sticky backed heat sinks found in your hardware bag to the motor controller shield. Use black rubber bands to keep the heat sinks in place.

Step 3: Connect The Motors

Attach the motors to the motor controller shield. Note that the motors connect to ports 1 and 3 not 1 and 2.

Port 3 controls the left motor and Port 1 the right motor (as viewed when facing the MaslowCNC). The cables have two sides, one side is notched, do not force the cables in the wrong orientatio. The Z axis motor is connected to port 2.

Step 4: Connect The Power Supply

Plug the 12V power supply into the motor controller shield. Note that the power supply plugs into the motor controller shield and not to the microcontroller. We have put a rubber plug or sticker over the port that should not be used.

Plugging the power supply into the Arduino will not damage it, but it also will not provide power to the motors.

Step 5: Connect The USB Cord

Plug the USB cord into the Arduino and into your computer. Note that the 'USB' light will come on to indicate that the board is connected and receiving power from your computer.

Programming Arduino and Installing Ground Control Software

The arduino already has version 1.26 firmware installed!!! We pre-loaded it and tested the motors to make sure you have a working board. You only need to download the ground control software to your pc. Instructions for that are located here:

http://maslowcommunitygarden.org/GroundControl.html?instructions=true

Building the Frame

Instructions for building either the default frame or the bolt together frame are located at the link below:

https://github.com/MaslowCNC/Mechanics/wiki/Choose-A-Frame-Design

Please note we recommend making the machine one foot taller and also making the top motor mounting bar 12' long instead of 10 ' long.

The easiest way to do this is to just make the default frame but buy an extra 12' long 2x4'. Mount this ontop of the exsisting 2x4x10 top bar on the skinny 1.5' edge using some 8' long carriage bolts.

Having the motors further out makes corner cutting more accurate.

Assembling the Final Sled

Since our kit comes with a laser cut sled with rounded UHMW trim there is no need to make a temporary sled or final sled. You just need to attach the Z axis C beam, router clamp, and linkage arms. Total time about 15 minutes. See below for step by step photos. Use blue thread lock on all screws!

1. Attach the linkage arms to the sled with the 4 included coutersunk machine screws 1/4-20 x 1' long using a phillips screw driver. ALL PICTURES BELOW SHOWS THE ARMS IN WRONG ORIENTATION. PLEASE HAVE THE SMALL CENTER HOLE AS FAR AWAY FROM THE CENTER OF THE SLED.

2. If you are using the Makita Router then you can take another 4 screws and attach the clamp to the z axis. If you are using the dewalt or 3.5' router clamp then one must remove the plate from the z axis and screw from the back.

Remove the black machine screws from the bottom of the 200mm z axis and slide out the carriage. BE CAREFUL not to let bearings or washers drop and get lost.

Attach the clamp to the black plate using 4 counter sunk screws

Then put the black bottom part of the z axis back on (but leave the original black screws out)

3. Next take 4 of the 5mm flat head screws and attach the z axis to the sled. It is easiest to screws in all 4 screws loosely and then tighten them up once it is aligned. Remember to use blue thread lock)

4. To attach the z axis motor to the z axis take the black motor bracket and attach it to the T nuts using the 2 short machine screws . Please do not remove the hot glue/butyle tape from the T nuts in the z axis. The T nuts have a tendency to come out if that is done.

Maslow Cnc Assembly

5. Once the bracket is in place you will need to secure the motor with the shafts as close as possible together with 6 small machine screws.

6. Next attach the Gt2 Belt and the 2 gears to the two top shafts. The 2 gears have different inner diameters to fit on the two different shafts. The best way to do this is to put the belt on the two gears and then simultaneoulsy slide both gears and belt on the shaft. Tighten down the set screws using the 2mm allen key.

7 Lastly. Attach the chain to the linkage arms using the included cotter pins. Spread ends out to secure in place.

That's it! your final sled should look like the photo below.

12 Foot Maslow Cnc Frame

Now includes a FREE upcut bit!!

In stock now, all you need to start projects today!

In stock with free projects, software, and support all included. Ships same day.

Original Maslow + Metal Sled, Cbeam Z axis, Arduino enclosure & more.

Our complete kit takes off where the orginal left off with many upgraded features and quicker assembly times.

Make your designs come to life with the Maker Made 1/4' CNC Bit.

Set of 2 drive chains

GRBL based motor shield for use with Arduino DUE micro-controller board (not included).

The perfect bit for making signs and detailed cuts like lettering!

A bundle of our most popular bits, this 3-pack of 1 Up cut, 1 Down cut, and 1 Compression router bit provides a great starter set of bits for your most common cutting needs, at a nearly 15% savings versus buying individually. All three bits are solid carbide, with a 0.25in diameter shank and overall length of 2.5in.

Ring and bearing kit that ensures smooth and accurate cuts on your Maslow CNC.

1/4' Spiral Up Cut Bits

1/4' CNC Compression Bit

The complete Z-Axis kit for the Maslow CNC. Automates the cut depth of the router bit.

The latest shield v1.4 offers many improvements over it's predecessor.

This is a kit to build a linkage system for a Maslow CNC machine that enables triangular kinematics (as opposed to quadrilateral kinematics) for more accurate cuts and a more stable router sled.

One Motor/Encoder/Gear Box Unit. These are identical to the motors in the original Maslow kit and are surplus from the last batch of kits sold.

One pair of Sled Ring Bearing Carriages to hold bearings as the roll along sled rings.

CNC Laser Cut 12 lb base with 7' long arm linkage kit & z axis compatable with most routers

Maslow Cnc Setup

Two 6 ft long bars with coupler and laser cut holes to mount the motors 10' or 12' apart

Surplus hardware bag from Maslow kits

Maslow Cnc Frame

A surplus Maslow hardware bag

Bosch POF 1200 Z-axis kit 2.0

The Maslow Arduino shield version 1.2b

Maker Made Maker300 3D Printer

Maslow Cnc Metal Frame

This L bracket is used to attach the ring to the sled and two of them together are used to hold the z-axis motor.

Maslow Power Supply with US Plug

One set of (4) sled ring bearings.

One Keyestudio MEGA 2560 R3 micro controller (Arduino compatible) with USB cord + extension to connect to your computer.

Maslow Cnc Sled

Maslow power supply with EU plug

Made with higher grade materials than original motors. Direct from manufacturer.